thickness: 0.3-25mm

8849 NT High pressure laminate Sheet: Key Features, Applications, and Industry Trends

High Pressure Laminate (HPL) sheets, such as the 8849 NT High pressure laminate sheet, are increasingly popular in a range of industries for their durability, aesthetic appeal, and practical functionality. These materials have become essential in sectors like construction, interior design, and furniture manufacturing, offering a cost-effective solution for a variety of surface needs. In this article, we will examine the market demand, technical details, manufacturing process, and application of 8849 NT HPL, and explore key industry trends and challenges that shape its future.

The HPL market has experienced sustained growth over the years, driven by rising demand for materials that provide both aesthetic appeal and high-performance characteristics. Particularly in the commercial, residential, and industrial sectors, there is a strong preference for materials that are durable, easy to maintain, and versatile. HPL sheets, such as the 8849 NT, are ideal for these applications due to their resistance to moisture, heat, and scratches, making them particularly suitable for high-traffic areas such as kitchens, bathrooms, and office spaces.

As consumers become more conscious of sustainability and environmental impact, the demand for eco-friendly materials is also on the rise. This shift has influenced HPL manufacturers to focus on producing laminates with less environmental impact, while maintaining high-quality standards. The 8849 NT HPL Sheet is an example of a product designed to meet the growing need for both high performance and environmental responsibility.

At its core, 8849 NT High Pressure Laminate Sheet is produced through the high-pressure laminate process, a technique that involves the fusion of multiple layers of resin-impregnated paper under extreme pressure and heat. This manufacturing process results in a dense, durable material with outstanding resistance to external elements such as stains, scratches, heat, and chemicals.

The key technology behind HPL sheets involves the use of decorative and core layers. The decorative layer, often printed with intricate designs or textures, provides the visual appeal of the laminate. Beneath it, the core layers—typically made from kraft paper and resin—give the laminate its structural integrity, providing the strength and durability necessary for demanding applications. The final result is a material that balances both aesthetic qualities and high performance.

The 8849 NT HPL Sheet consists of several critical layers, each contributing to its overall performance:

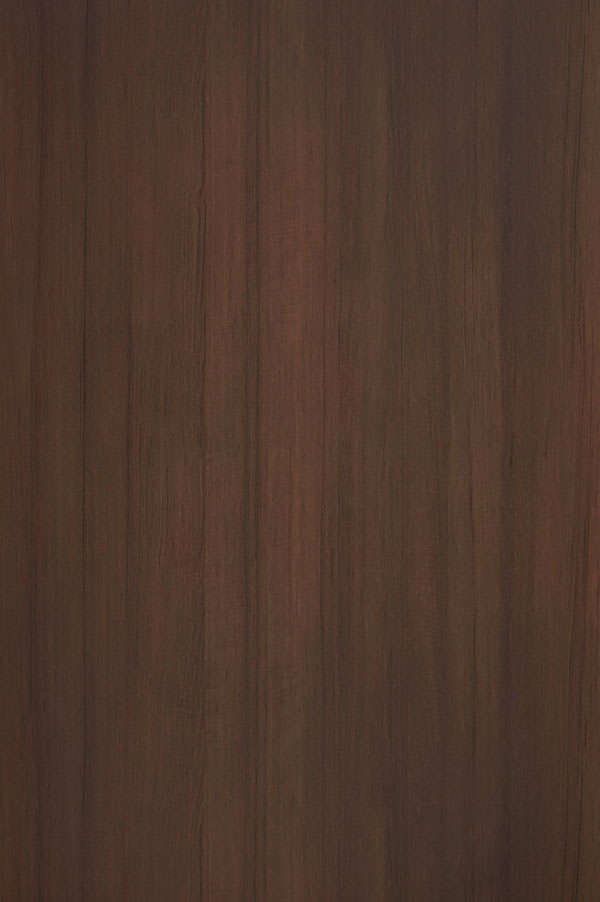

Decorative Layer: The topmost layer, which is usually printed with vibrant patterns, textures, or solid colors. This layer is designed for aesthetic appeal and can mimic natural materials like wood, stone, or metal.

Core Layers: Made of several layers of kraft paper impregnated with phenolic resin, these layers provide the strength, stability, and resistance needed for the laminate. The core layers also ensure the material’s durability under high pressure and heat.

Protective Overlay: This layer is designed to provide resistance against everyday wear and tear, including scratches, stains, and moisture. The quality of the protective overlay plays a significant role in the laminate’s overall longevity.

Back Layer: The back layer helps stabilize the laminate sheet and prevents warping, ensuring that the sheet maintains its flatness during use.

The manufacturing process involves applying extreme pressure (typically between 1000-1500 psi) and heat (around 140°C) to bond these layers together, creating a strong and durable sheet. This process also enhances the laminate’s resistance to heat, moisture, and impact, making it ideal for a wide range of applications.

The quality and performance of 8849 NT High Pressure Laminate Sheet can be influenced by several key factors:

Resin Quality: The type and quality of resin used in the laminate’s core layers significantly affect its resistance to stains, moisture, and heat. High-quality resins ensure that the laminate remains durable over time.

Layer Composition: The number of layers and their specific composition can impact the laminate’s strength, impact resistance, and overall durability. A higher number of layers typically results in a stronger laminate, which can withstand higher levels of wear and tear.

Thickness: Thicker laminates generally offer better performance in terms of impact resistance and longevity. However, thicker laminates may be less flexible and harder to cut or install.

Surface Texture: The texture of the laminate surface can affect its visual appeal as well as its functionality. A matte finish may be preferred for its ability to resist fingerprints and scratches, while glossy finishes are often used for modern, sleek aesthetics.

Pressing Conditions: Variations in the temperature and pressure during the manufacturing process can directly impact the laminate’s quality. Proper control of these parameters is crucial to ensure the laminate’s resistance to external factors such as moisture and UV radiation.

When selecting a supplier for 8849 NT High Pressure Laminate Sheets, several factors should be considered:

Material Quality: Suppliers should be able to provide high-quality raw materials that meet international standards. This is crucial for ensuring that the final product exhibits the desired durability and performance characteristics.

Customization Options: Many suppliers offer the ability to customize the laminate in terms of color, texture, and finish. Customization is important for meeting the unique design needs of clients across various industries.

Lead Time and Reliability: A reliable supplier should be able to provide consistent lead times and meet deadlines, especially in large-scale construction or manufacturing projects.

Certifications: It is important to choose a supplier that adheres to relevant quality certifications, such as ISO 9001 or ISO 14001, to ensure consistent quality and sustainable manufacturing practices.

Despite its numerous advantages, the HPL industry faces several challenges:

Sustainability: Although HPL is known for its durability, the production process can involve the use of chemical resins, which may not be fully eco-friendly. There is an increasing demand for more sustainable HPL solutions, and manufacturers are looking for ways to reduce the environmental impact of their products.

Impact Resistance: While HPL is durable, it is not entirely resistant to high-impact forces. In environments where extreme impact is common, HPL may be prone to cracking or chipping.

Cost Variability: The price of HPL can vary depending on factors such as material quality, customization options, and supply chain fluctuations. This can pose a challenge for businesses that need to maintain consistent pricing in competitive markets.

The 8849 NT High Pressure Laminate Sheet is used in a variety of applications, including:

Furniture Manufacturing: HPL sheets are widely used for producing durable and stylish furniture surfaces, including tabletops, cabinet doors, and shelving units.

Interior Design: In both commercial and residential spaces, HPL is used for wall panels, flooring, and countertops, thanks to its resistance to moisture and stains.

Retail and Hospitality: High-traffic areas such as shopping malls, hotels, and offices benefit from the strength and low-maintenance requirements of HPL surfaces.

Construction: HPL is commonly used for cladding in buildings, providing both aesthetic appeal and practical protection against the elements.

The demand for HPL sheets like the 8849 NT is expected to grow as industries continue to prioritize sustainability and high-performance materials. Trends such as the use of digital printing technology, eco-friendly resins, and customizable designs are likely to shape the future of the HPL market. The increasing focus on aesthetic versatility, alongside durability and sustainability, will continue to drive the innovation and evolution of HPL products.

Q1: How does the 8849 NT HPL sheet differ from other laminates?

A1: The 8849 NT HPL sheet offers enhanced durability and resistance to moisture, stains, and heat compared to standard laminates, making it ideal for high-traffic and high-moisture environments.

Q2: Can the 8849 NT HPL sheet be used for outdoor applications?

A2: While it performs excellently in indoor applications, outdoor use may require laminates specifically designed to resist UV radiation and extreme weather conditions.

Q3: What are the maintenance requirements for HPL surfaces?

A3: HPL surfaces are relatively low-maintenance, requiring only regular cleaning with non-abrasive solutions. Avoiding harsh chemicals and excessive heat will extend the lifespan of the material.

RELATED

RELATED

+86 13616452113

info@hpl.cc

East of Huaihai Road, Nanwang Industrial Park, Penglai District, Yantai City, Shandong Province

©2025- Monco HPL All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.