Antimicrobial Compact laminate: Revolutionizing Hygiene and Durability in Modern Spaces

In today's fast-paced world, the importance of maintaining hygienic environments in both commercial and residential settings has never been more crucial. With growing awareness around cleanliness and infection control, industries such as healthcare, hospitality, education, and food service are constantly seeking materials that can combine aesthetic appeal with high-performance hygiene solutions. One such material that has gained significant traction is Antimicrobial Compact Laminate. This article explores the rise of antimicrobial compact laminate, its core properties, applications, and its role in shaping the future of surface materials.

Industry Background and Market Demand

The demand for antimicrobial materials has surged in recent years, particularly in the wake of global health concerns such as the COVID-19 pandemic. As cleanliness and sanitation became top priorities, industries sought materials that could resist the growth of harmful microbes, providing not only functional benefits but also peace of mind for users. Compact laminate, traditionally known for its durability and versatility, has evolved to incorporate antimicrobial properties, making it a game-changer in various sectors.

The need for antimicrobial solutions is especially prominent in spaces like hospitals, schools, commercial kitchens, and public restrooms, where high traffic and constant exposure to germs make surfaces prone to contamination. The antimicrobial compact laminate addresses these needs by combining the durability of traditional laminate with a built-in defense against bacteria, fungi, and viruses. This shift towards antimicrobial materials is also driven by stricter regulations regarding hygiene standards, particularly in healthcare and food service industries.

Core Concepts and Key Technologies

Antimicrobial compact laminate is a surface material that integrates antimicrobial agents into its structure, preventing the growth and spread of harmful microorganisms. The technology behind antimicrobial laminates typically involves the incorporation of substances like silver ions or copper particles into the laminate layers. These ions disrupt the metabolic processes of microorganisms, rendering them inactive and preventing their proliferation on the surface.

The key technology behind antimicrobial compact laminate is the incorporation of antimicrobial additives during the manufacturing process. These additives are embedded into the laminate resin or surface coating, ensuring long-lasting protection against microbes without compromising the material's strength, appearance, or ease of maintenance.

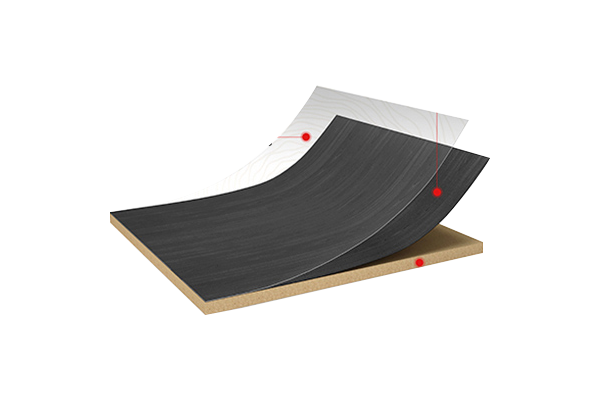

Structure, Performance, and Manufacturing Process

Antimicrobial compact laminate is created through a multi-step manufacturing process. The core material is typically made from layers of kraft paper impregnated with phenolic resin. This core is then sandwiched between layers of decorative paper and a final protective layer that includes the antimicrobial agents. The laminate is then compressed under high pressure and temperature, which solidifies the structure and enhances its durability.

The performance of antimicrobial compact laminate is largely determined by its ability to resist scratches, stains, and moisture. These attributes are crucial for high-traffic environments where surfaces must withstand constant use and cleaning. Additionally, the antimicrobial properties do not wash away or degrade over time, providing continuous protection without the need for special maintenance.

The laminate is available in various finishes, including matte, gloss, and textured, allowing for versatility in design. Despite the addition of antimicrobial agents, the laminate maintains its aesthetic appeal, offering a wide range of colors and patterns to suit any space.

Factors Influencing Quality and Performance

Several factors influence the quality and performance of antimicrobial compact laminate. The type of antimicrobial agent used is a key factor; silver-based additives are the most commonly used due to their proven efficacy and non-toxic properties. The concentration of these agents also plays a critical role in the laminate’s effectiveness. A higher concentration may provide more robust protection but could potentially affect the laminate’s appearance or performance if not properly balanced.

Additionally, the manufacturing process itself is critical. The uniformity of the application of antimicrobial agents and the integrity of the laminate layers determine the overall effectiveness and longevity of the product. High-quality antimicrobial compact laminates are engineered to maintain their antimicrobial properties even after extensive use, ensuring long-term protection in demanding environments.

Supply Chain and Supplier Selection Criteria

When selecting suppliers of antimicrobial compact laminate, businesses should consider several key factors. First, it’s essential to ensure that the supplier follows industry standards and regulations for antimicrobial products. Certifications such as ISO 22196 or ASTM E2180, which measure antimicrobial activity, can provide a benchmark for the product’s efficacy.

The supplier's manufacturing capabilities and product consistency are also important. Suppliers that use high-quality materials and advanced production techniques will ensure that the laminate's performance remains reliable over time. Furthermore, the ability to customize designs and finishes can be a crucial consideration, particularly for architectural firms and interior designers who require specific aesthetic features for their projects.

Common Issues and Industry Challenges

Despite its many advantages, antimicrobial compact laminate is not without its challenges. One of the most common concerns is the misconception that antimicrobial properties replace regular cleaning and maintenance. While antimicrobial laminates help reduce the growth of harmful microbes, they are not a substitute for routine cleaning. Neglecting surface care can still lead to the buildup of dirt, grime, and bacteria, undermining the laminate’s protective properties.

Another issue is the cost of antimicrobial laminates, which can be higher than standard laminates due to the additional technology and manufacturing processes involved. However, when considering the long-term benefits in terms of hygiene and reduced maintenance costs, the investment is often justified, especially in commercial and high-traffic environments.

Applications and Use Cases

Antimicrobial compact laminate is used in a variety of applications across industries:

Healthcare: Hospitals, clinics, and medical facilities use antimicrobial compact laminate for countertops, wall panels, and furniture. The material’s ability to resist bacterial growth makes it ideal for environments where cleanliness is paramount.

Foodservice: In commercial kitchens and dining areas, antimicrobial laminate is used for countertops, tables, and workstations, ensuring that surfaces remain hygienic despite constant exposure to foodborne pathogens.

Education: Schools and daycare centers benefit from antimicrobial compact laminate for desks, tabletops, and walls, helping maintain a cleaner and safer environment for students and staff.

Public Spaces: In public restrooms, transportation hubs, and shopping malls, antimicrobial laminate helps reduce the spread of germs on frequently touched surfaces.

Current Trends and Future Directions

The future of antimicrobial compact laminate looks promising, with advancements in material science and antimicrobial technology. Research into more sustainable and eco-friendly antimicrobial agents is underway, with a focus on reducing the environmental impact of these materials. Additionally, as the demand for hygienic solutions continues to grow, manufacturers are exploring new ways to improve the laminate’s durability, performance, and antimicrobial effectiveness.

Furthermore, the integration of smart technologies, such as self-cleaning surfaces or sensor-driven cleaning systems, could further enhance the functionality of antimicrobial compact laminates, offering even more advanced hygiene solutions.

Conclusion

Antimicrobial compact laminate represents a significant advancement in surface materials, offering a solution that combines durability, aesthetics, and hygiene. As industries continue to prioritize cleanliness and sanitation, the role of antimicrobial laminates will only become more important. By understanding the core properties, applications, and future trends of antimicrobial compact laminate, businesses can make informed decisions that support both their operational needs and the health and safety of their customers and employees.

FAQ (Frequently Asked Questions)

What is antimicrobial compact laminate?

Antimicrobial compact laminate is a surface material that incorporates antimicrobial agents to prevent the growth and spread of bacteria, fungi, and other harmful microorganisms.Where can antimicrobial compact laminate be used?

It is commonly used in healthcare, foodservice, education, and public spaces, including countertops, walls, and furniture, to maintain a cleaner and safer environment.How long do antimicrobial properties last in compact laminate?

The antimicrobial properties of compact laminate are designed to last for the lifespan of the material, even with regular cleaning and use. However, routine maintenance is still required.Is antimicrobial laminate a substitute for cleaning?

No, while antimicrobial laminate helps reduce microbial growth, it is not a replacement for regular cleaning and disinfecting.

Phone

Phone