Scratch-Resistant Metal High-Pressure Laminate: A Durable Solution for Modern Applications

As the construction and interior design industries continue to evolve, the demand for durable, aesthetically pleasing, and functional materials grows. One such material that has gained significant popularity in recent years is scratch-resistant metal high-pressure laminate (HPL). Known for its durability, low maintenance, and versatility, scratch-resistant metal HPL is now a top choice for applications ranging from commercial interiors to residential projects. This article explores the industry background, key technologies, performance characteristics, supply chain factors, and application scenarios related to scratch-resistant metal HPL, shedding light on why it’s an ideal solution for high-traffic areas.

Industry Background and Market Demand

The demand for durable, easy-to-maintain surfaces has surged across various industries, particularly in commercial spaces, healthcare facilities, educational institutions, and residential designs. As spaces become more dynamic and usage intensifies, the need for materials that withstand wear and tear—while maintaining aesthetic value—becomes paramount. Scratch-resistant surfaces, in particular, are becoming increasingly important, especially for applications where high foot traffic or heavy use is expected.

In the realm of high-pressure laminates (HPL), the shift towards metal-infused solutions is an industry response to the growing need for not only durability but also modern aesthetics. Metal HPL offers the added benefit of scratch resistance, which is highly valued in sectors that prioritize cleanliness, longevity, and resilience. For example, in healthcare, where surfaces must endure constant cleaning without showing signs of damage, or in retail and hospitality, where aesthetics must align with durability, the material has proven to be highly effective.

Core Concepts and Key Technologies

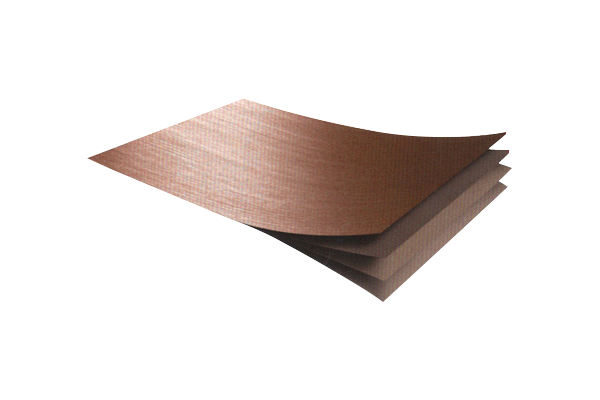

Scratch-resistant metal high-pressure laminate (HPL) is a layered Composite material created by fusing multiple layers of resin-impregnated paper with a Decorative surface, typically metal, under high heat and pressure. The result is a durable, non-porous material that combines the strength of metal with the versatility and aesthetic options offered by HPL. The core technology behind these panels lies in the combination of the right materials and processing techniques:

High-pressure lamination: The process of applying high heat and pressure allows the materials to bond at a molecular level, creating a rigid surface that is resistant to abrasion and impact.

Metal infusion: The introduction of metal into the laminate’s surface not only adds a sleek, modern look but also enhances its durability. Metal-infused HPL can include materials such as aluminum, stainless steel, or copper.

Scratch resistance: To improve scratch resistance, manufacturers incorporate specialized protective coatings or use harder metal surfaces. These coatings protect the HPL from everyday abrasions, ensuring that the material maintains its appearance and integrity over time.

Product Structure, Performance, Materials, and Manufacturing Process

Scratch-resistant metal HPL consists of several layers, each serving a specific function:

Decorative Layer: This is the visible surface layer, often a metal veneer or a decorative print on a resin-based substrate. This layer provides the aesthetic appeal and can be customized in various colors, textures, and finishes.

Core Layer: Typically made from kraft paper or other composite materials, the core provides the structural integrity of the laminate. This layer is critical in ensuring that the final product remains rigid and durable.

Protective Resin Layer: A final resin layer is applied to give the material its scratch-resistant properties. The resin helps to enhance both the physical and chemical resistance of the material, ensuring that it can withstand daily wear and tear.

The manufacturing process for scratch-resistant metal HPL involves several stages:

Layer Preparation: Each layer is carefully prepared, with the core being infused with resin to create the necessary bonding material for the surface layer.

Pressing: The layers are then stacked and subjected to high heat and pressure in a hydraulic press. This process bonds the layers together, creating a single, cohesive sheet of laminate.

Finishing: After pressing, the surface of the laminate may be treated with protective coatings or polished to achieve the desired texture and appearance.

Key Factors Influencing Quality and Performance

The performance of scratch-resistant metal HPL depends on several factors:

Material Selection: The type of metal used in the laminate’s surface plays a critical role in its durability. For example, stainless steel offers superior resistance to corrosion and scratching, making it ideal for high-traffic areas, while aluminum provides a lighter alternative.

Resin Quality: The resin used to bond the layers together and provide scratch resistance needs to be high-quality. Poor-quality resins may result in a weaker laminate that wears down faster.

Thickness of the Panels: Thicker panels are generally more durable and resistant to impact, but they may also be heavier and more difficult to handle during installation.

Protective Coatings: The type of coating used to improve the scratch-resistant properties of the laminate is crucial. Advanced coatings that enhance the hardness and resistance to abrasion are often employed to extend the life of the material.

Supply Chain and Supplier Selection Criteria

When sourcing scratch-resistant metal HPL, selecting the right supplier is essential to ensure product quality and consistency. Here are several factors to consider:

Quality Control: Suppliers should adhere to strict quality control standards, ensuring that every batch of laminate meets the required durability and aesthetic standards.

Customization: Look for suppliers who offer customization options, including a variety of metal finishes (e.g., matte, gloss, brushed) and sizes, allowing flexibility in design and application.

Sustainability: As sustainability becomes a growing concern, it's important to choose suppliers who are committed to using recycled materials or employing eco-friendly manufacturing processes.

Lead Time: Ensure that suppliers can deliver the required quantities on time, particularly for large projects or tight deadlines.

Common Challenges and Industry Pain Points

Despite its many benefits, there are some challenges associated with using scratch-resistant metal HPL:

Cost: High-quality metal-infused HPL can be more expensive than traditional laminate or other surface materials. However, its long lifespan and minimal maintenance costs can make it a worthwhile investment in the long run.

Installation Complexity: Due to the strength and rigidity of the material, installation of scratch-resistant metal HPL may require specialized tools and techniques, which could increase labor costs.

Material Compatibility: Not all adhesives or bonding agents are compatible with metal HPL, which may require specific solutions to ensure a secure installation.

Application Scenarios and Industry Use Cases

Scratch-resistant metal high-pressure laminate is used in various sectors where durability and aesthetic appeal are essential:

Commercial Interiors: In retail environments, restaurants, and offices, the material is ideal for creating high-traffic surfaces like countertops, tables, and wall panels that must resist daily wear and tear.

Healthcare: In hospitals and medical centers, scratch-resistant metal HPL is often used for surfaces in patient rooms, laboratories, and waiting areas, offering both hygiene and durability.

Residential Design: For modern kitchens, bathrooms, and living spaces, scratch-resistant metal HPL offers a stylish, long-lasting surface that resists stains, scratches, and moisture.

Public Spaces: Airports, transportation hubs, and museums benefit from using this material for walls and furniture, where durability is crucial.

Current Trends and Future Directions

As the demand for sustainable and resilient building materials increases, manufacturers of scratch-resistant metal HPL are focusing on innovations such as:

Eco-friendly formulations: Incorporating recycled metals and low-emission production processes to reduce the environmental impact of manufacturing.

Smart materials: The integration of smart technologies in HPL, such as coatings that change color with temperature or humidity, could be a future direction for advanced surface solutions.

Customization and Design: With increased demand for personalized interiors, more suppliers are offering bespoke designs, allowing for greater creativity in architectural applications.

Conclusion

Scratch-resistant metal high-pressure laminate provides a versatile, durable, and aesthetic solution for various applications, from commercial spaces to residential interiors. As industries continue to prioritize both durability and sustainability, this material offers the perfect combination of long-lasting performance and visual appeal. With advancements in technology, materials, and manufacturing processes, scratch-resistant metal HPL is set to remain a key component of modern construction and design for years to come.

FAQ (Frequently Asked Questions)

What makes metal HPL scratch-resistant?

The addition of a high-quality resin coating and the use of durable metal surfaces, such as stainless steel, contribute to its scratch-resistant properties.Where can scratch-resistant metal HPL be used?

It is ideal for high-traffic areas such as countertops, wall panels, tables, and furniture in commercial, residential, and healthcare environments.Is metal HPL more expensive than regular laminate?

Yes, it can be more expensive due to its high-quality materials and manufacturing processes. However, its durability and low maintenance can offset the initial cost in the long term.Can metal HPL be customized?

Yes, metal HPL is available in various finishes and can be customized to meet specific size and design requirements for different projects.

Phone

Phone